Plunger Pump KTZ350

Product Features

Main structural characteristics:

1. Primarily composed of the PG series power end assembly and the TH series fluid end assembly.

2. Features a double-key eccentric wheel structure for the crankshaft, with double-arc helical gears mounted at both ends of the crankshaft to transmit power and counteract axial forces.

3. The power end and the fluid end are connected by 8 alloy steel tie rods. When removing the fluid end, the tie rods remain attached to the power end.

4. The connection between the plunger and the crosshead uses threaded connections, making disassembly and maintenance of the fluid end easy.

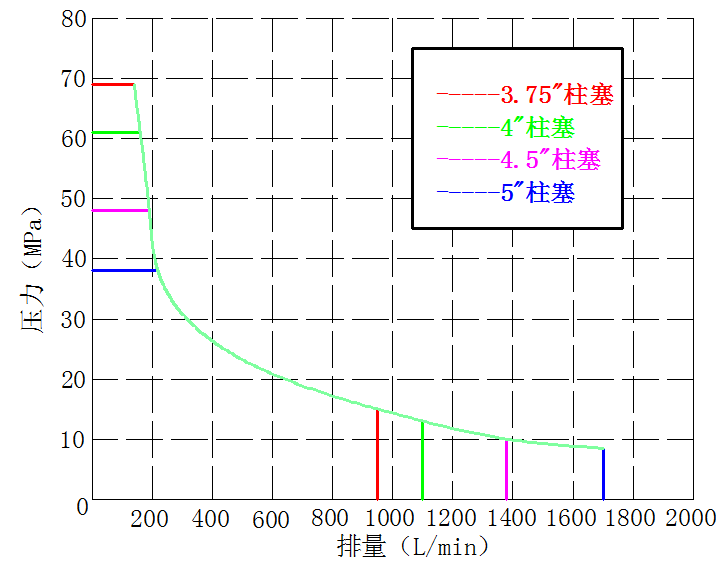

5. The fluid end allows for four different plunger sizes (3.75", 4", 4.5" and 5") with the same pump head to achieve various displacements and pressures for customer selection.

Product Parameters

|

|

|

||||||||||||||||||||

Operating parameters

Performance Parameters:

(Note: The parameters in the table are calculated based on 100% volumetric efficiency and 90% mechanical efficiency.)

|

Plunger Diameter (inches) (mm) |

Pump Strokes (rpm) |

||||||||||

|

50 |

100 |

200 |

300 |

350 |

|||||||

|

Displacement GPM (L/min) |

Pressure Psi (MPa) |

Displacement GPM (L/min) |

Pressure Psi (MPa) |

Displacement GPM (L/min) |

Pressure Psi (MPa) |

Displacement GPM (L/min) |

Pressure Psi (MPa) |

Displacement GPM (L/min) |

Pressure Psi (MPa) |

||

|

3.75" (95.25) |

36 (136) |

10000 (68.9) |

72 (271) |

7658 (52.8) |

143 (543) |

3829 (26.4) |

215 (814) |

2553 (17.6) |

251 (950) |

2190 (15.1) |

|

|

4" (101.6) |

41 (154) |

8790 (60.6) |

82 (309) |

6715 (46.3) |

163 (618) |

3365 (23.2) |

245 (927) |

2234 (15.4) |

286 (1081) |

1915 (13.2) |

|

|

4.5" (114.3) |

52 (197) |

7000 (48.3) |

103 (391) |

5308 (36.6) |

207 (782) |

2654 (18.3) |

310 (1173) |

1769 (12.2) |

366 (1368) |

1523 (10.5) |

|

|

5" (127) |

64 (241) |

5500 (38) |

128 (483) |

4293 (29.6) |

255 (965) |

2147 (14.8) |

383 (1448) |

1436 (9.9) |

446 (1689) |

1233 (8.5) |

|

|

Input Power |

175kW |

265kW |

265kW |

265kW |

265kW |

||||||