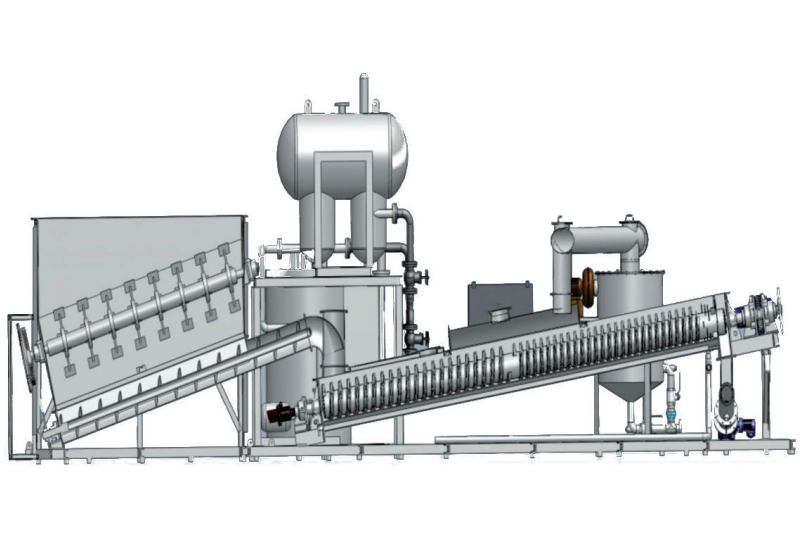

Oily sludge drying equipment

The oil sludge drying equipment is mainly used for drying highly stable emulsified systems formed by water-in-oil, oil-in-water, and suspended solid impurities. By indirectly heating the oil and water, and using a low-speed hollow screw to push the material, it achieves the drying of the oil sludge and the output of dry material. The oil-containing gas from the top outlet is further cooled and the oil-containing wastewater is collected through a condensation and circulation process.

Product Features

By adjusting the rotation frequency, the moisture content of the sludge can be controlled within 10%.

High heat transfer efficiency and low energy consumption.

The oil can be thermally desorbed and used to heat the thermal oil, achieving self-sufficiency.

Good sealing, effectively controlling odors.

Available in single, double, or triple unit structures, with adjustable blade pitch.

The blades are equipped with scrapers, allowing self-cleaning of oil sludge on the blades, ensuring heat transfer efficiency.

The entire process can be PLC controlled with a high degree of automation.

Safe and simple operation, requiring minimal expertise from the operators.

Product Parameters

Feed Amount: 20% moisture, 19,201 kg/h

Dry Output: Moisture 10-11%, 17,076-17,281 kg/h

Number of Screws: 4

Speed: 1.73-6.86 r/min

Rated Pressure: 1.03 MPa